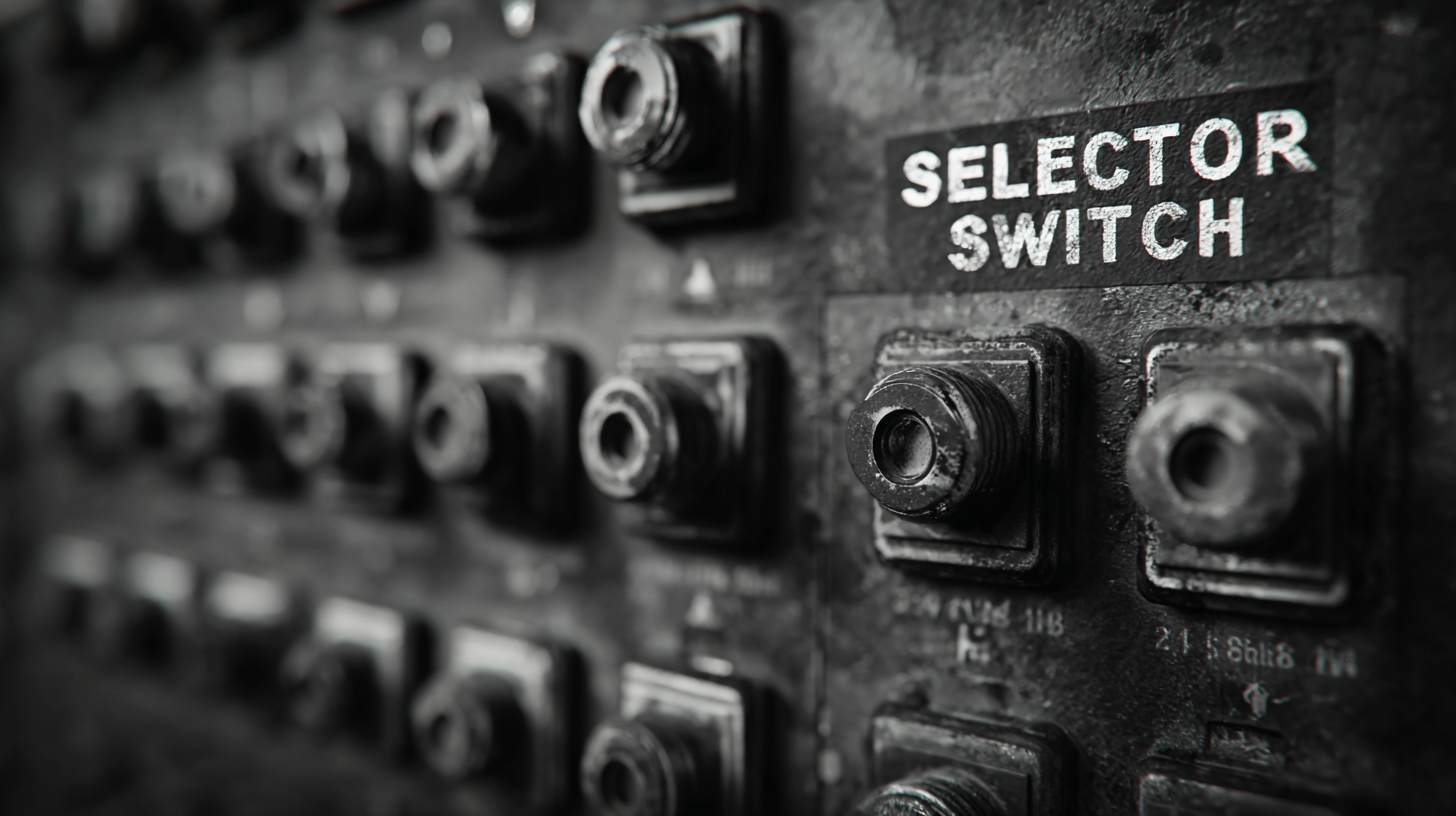

The Ultimate Guide to Choosing the Best Selector Switch for Your Industrial Needs

In the ever-evolving landscape of industrial automation, selecting the right components is crucial for maximizing operational efficiency and safety. Among these components, the Selector Switch emerges as a vital element, facilitating the control and selection of machinery operations. According to a recent report by Allied Market Research, the global market for industrial control equipment, including Selector Switches, is projected to reach $30 billion by 2027, driven by advancements in automation technologies and increased demand for reliable control systems.

Selecting the best Selector Switch not only influences equipment performance but also impacts maintenance cost and user experience. As industries strive for greater flexibility and productivity, understanding the critical features and varieties of Selector Switches becomes imperative for ensuring compliance with operational requirements and enhancing overall system reliability. This ultimate guide aims to provide essential tips and insights to help you navigate the selection process effectively.

Understanding Selector Switch Types and Their Applications in Industry

When selecting a selector switch for industrial applications, understanding the various types available and their specific uses is crucial. Selector switches can be categorized based on their design and function, including traditional electromechanical switches and advanced smart selectors that integrate with digital systems. The industrial sector's increasing demand for automation and control has driven the market for these switches, which is expected to witness significant growth. According to industry reports, the global market for electric motor control centers, encompassing selector switches, is projected to reach several billion dollars by 2025, driven by advancements in industrial automation and smart manufacturing.

In addition to the type of selector switch, its application can vary depending on voltage levels, categorized into low voltage and medium voltage systems. Traditional motors dominate the market; however, the rise of intelligent motors is reshaping demand dynamics. Understanding the components involved is equally important, as selector switches are often integrated with busbars, circuit breakers, fuses, and relays, creating a comprehensive control solution. The shift towards integrated systems affirms the importance of selecting the right switch type to meet the operational demands of modern industry, ensuring efficiency and reliability in motor control applications.

Key Industry Standards and Certifications for Selector Switches

When selecting a selector switch for industrial applications, understanding key industry standards and certifications is crucial. These benchmarks ensure that the products you are considering meet specific safety, performance, and reliability criteria essential for industrial environments.

Standards such as IEC 60947-1 and UL 508 provide guidelines for the design and performance of selector switches, ensuring they can withstand harsh conditions and maintain functionality over time.

Additionally, certifications like CE marking and UL listing indicate that a switch complies with European safety directives and American safety standards, respectively. These markings not only enhance your confidence in the product but also support regulatory compliance in your operations. By selecting switches that adhere to these established standards and certifications, you minimize risks and ensure that your equipment functions efficiently and safely in demanding industrial applications.

Factors Influencing the Selection of Selector Switches in Industrial Settings

When selecting the best selector switch for industrial applications, several factors come into play. The increasing demand for industrial automation is a significant driver for the electromechanical switch market, projected to reach a market size of $4.58 billion by 2024. As production lines become more automated, the need for reliable and precise control mechanisms intensifies. Selector switches play a crucial role in ensuring operational efficiency and safety in highly automated environments.

**Tips:** Consider the electrical ratings and compatibility of the selector switch with your existing equipment. Ensure that the switch can handle the specific voltage and current requirements of your application. Additionally, assess the environmental conditions in which the switch will operate, such as exposure to dust, moisture, or extreme temperatures.

Another critical aspect is the ease of use and accessibility of the selector switch. In a fast-paced industrial setting, operators must be able to quickly and accurately change settings without extensive training. Incorporating ergonomic design features can greatly enhance usability. The global data center switch and equipment market, valued at approximately $3.21 billion in 2023, further emphasizes the importance of user-friendly interfaces in these controls, projecting significant growth in the coming years.

**Tips:** Regularly review and update your selection process to adapt to evolving industry trends, as well as to incorporate the latest technological advancements that could improve overall efficiency and safety in your industrial operations.

The Ultimate Guide to Choosing the Best Selector Switch for Your Industrial Needs

| Feature | Importance | Key Considerations | Typical Applications |

|---|---|---|---|

| Durability | High | Material quality, resistance to harsh environments | Manufacturing, Heavy machinery |

| Ergonomics | Medium | Ease of use, accessibility for operators | Control panels, User interfaces |

| Electrical Ratings | High | Voltage, current ratings, and safety standards | Motor controls, Circuits |

| Type of Actuation | High | Manual, automatic, or remote operation preferences | Automated systems, Operator stations |

| Size and Mounting | Medium | Space constraints, panel cut-out dimensions | Control cabinets, Equipment enclosures |

Comparative Analysis of Selector Switch Performance Metrics

When selecting a selector switch for industrial applications, performance metrics play a crucial role in ensuring optimal functionality and reliability. The most commonly evaluated metrics include durability, switching speed, and resistance to environmental factors. Durability is often measured in terms of mechanical life cycles, while switching speed should align with the operational demands of your equipment. Additionally, understanding the environmental resistance of a switch, such as its IP rating, ensures that it can withstand conditions like dust, moisture, or temperature fluctuations that are typical in industrial settings.

**Tips:** Always opt for a selector switch that features high-quality materials and construction to enhance its lifespan and reliability. It’s also beneficial to conduct a thorough analysis of the manufacturer's specifications related to performance metrics. Consulting user reviews and case studies can give valuable insights into how specific models perform in real-world applications.

Furthermore, consider the ease of installation and maintenance when choosing a selector switch. The design should facilitate not only quick setup but also straightforward troubleshooting and repairs. Simple installation processes can significantly reduce downtime, which is critical in fast-paced industrial environments. Look for switches that come with detailed documentation and support, as this can save time and resources in the long run.

Emerging Trends in Selector Switch Technology for Modern Industries

Emerging trends in selector switch technology are reshaping modern industries, providing enhanced functionality and improved user experience. One notable trend is the integration of smart technology into selector switches. Advanced digital switches now feature programmable interfaces that allow for customization based on specific needs, significantly increasing operational efficiency. These smart selectors not only adapt to various industrial applications but also offer connectivity options for remote monitoring and control, aligning with the growing demand for automation.

When selecting a modern selector switch, consider the importance of ruggedness in industrial environments. Opt for switches that are designed to endure harsh conditions, including dust, moisture, and extreme temperatures. Additionally, it's essential to evaluate the ease of use; choose switches with clear labeling and tactile feedback to minimize confusion and errors during operation. This ensures that operators can quickly and accurately make selections, which is critical in fast-paced industrial settings.

Another emerging trend is the emphasis on energy efficiency. Many manufacturers are now producing selector switches that consume less power while maintaining high performance levels. This shift not only supports sustainability efforts but also reduces operational costs. When choosing a selector switch, look for models that comply with energy-saving certifications to maximize both efficiency and sustainability in your operations.