Leading Global Manufacturing: The Premier Source for Best Cam Switch Solutions

In today’s rapidly evolving manufacturing landscape, the demand for reliable and versatile electrical components is more vital than ever. According to a recent report by Market Research Future, the global cam switch market is expected to grow at a CAGR of 5.7% from 2021 to 2027, driven by the increasing automation and efficiency requirements across various industries. Among the myriad of options available, organizations are increasingly seeking the best cam switch solutions to enhance operational resilience and performance. This blog aims to explore the premier alternatives to traditional cam switches, shedding light on innovative designs and technologies that meet the dynamic needs of global manufacturing. By understanding these alternatives, manufacturers can optimize their systems and improve overall productivity, ensuring they remain competitive in a fast-paced market.

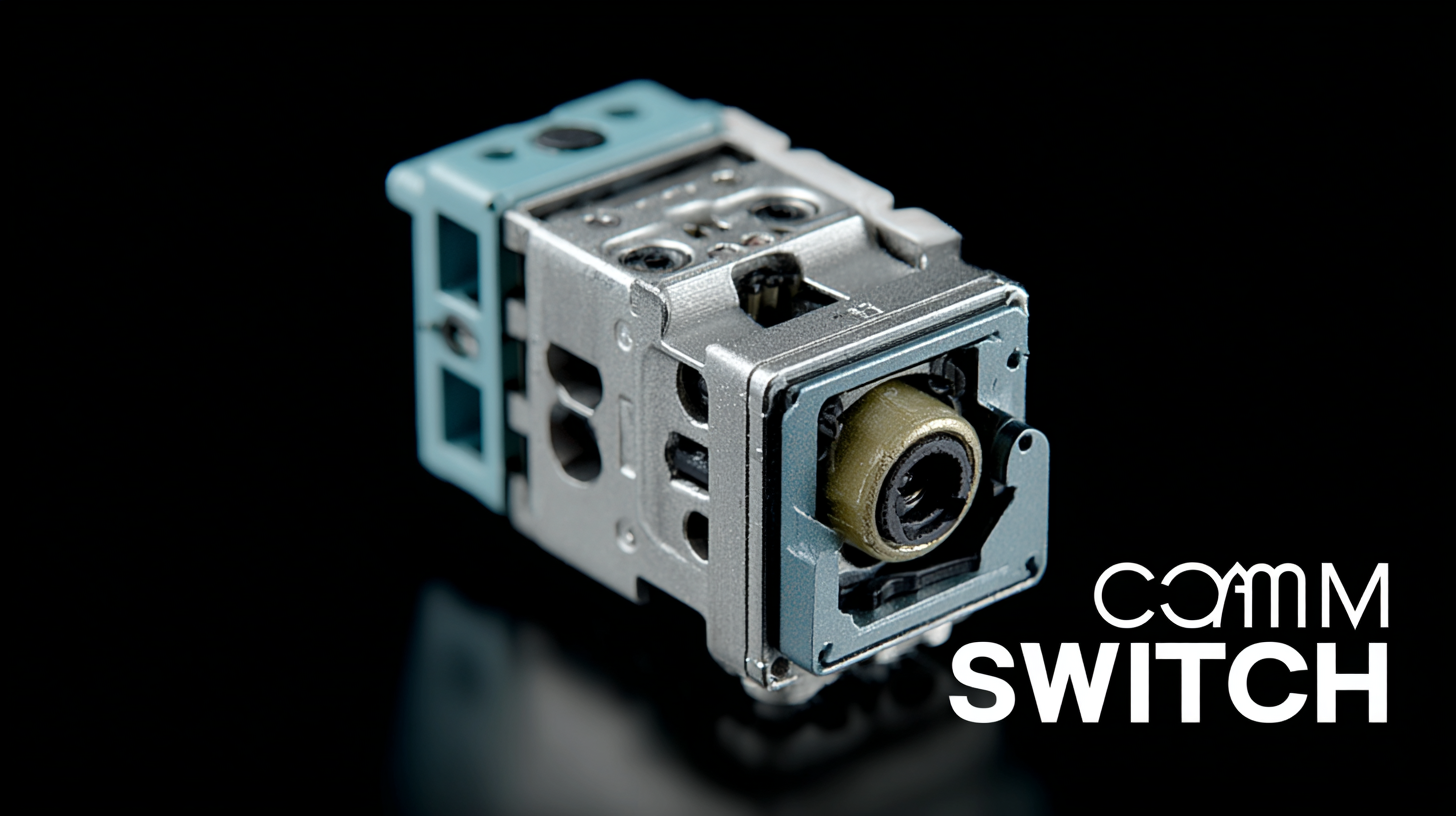

Unique Features of Advanced Cam Switch Solutions

When it comes to optimizing operational efficiency in various industries, advanced cam switch solutions stand out due to their unique features and functionalities. Unlike traditional switch designs, these state-of-the-art cam switches offer precision control that enhances the reliability of equipment. The robust construction of these switches ensures durability and longevity, making them an ideal choice for demanding manufacturing environments. Their ability to handle high electrical loads without compromising performance is a crucial advantage, positioning them as a top choice for global manufacturers.

In addition to their mechanical advantages, modern cam switches incorporate innovative technology that allows for greater flexibility and ease of use. Many models now come with customizable settings, enabling users to tailor operational parameters to specific requirements. Furthermore, ergonomic designs enhance user interaction, making it easier for operators to engage with complex machinery. As industries continue to evolve, the demand for advanced cam switch solutions that not only meet but exceed current standards is increasingly evident, solidifying their place as essential components in leading global manufacturing systems.

Key Advantages of Using High-Quality Cam Switches in Manufacturing

In the dynamic landscape of global manufacturing, the selection of reliable components plays a crucial role in ensuring operational efficiency and safety. High-quality cam switches are particularly essential due to their robust design and versatility. These switches are engineered to handle diverse applications, allowing manufacturers to achieve precise control over machinery and electrical systems. By utilizing these switches, facilities can minimize downtime, enhance productivity, and streamline their operational processes.

One of the key advantages of high-quality cam switches lies in their durability and longevity. Unlike inferior alternatives, premium cam switches are built to withstand harsh environments, reducing the likelihood of failure and ensuring consistent performance over time. Furthermore, many high-quality options offer customizable features, allowing manufacturers to tailor the functionality to specific operational needs. This adaptability not only improves workflow efficiency but also contributes to a safer workplace, as reliable switches reduce the risk of electrical faults and associated hazards.

Through the strategic implementation of top-grade cam switches, manufacturers can position themselves for success in an increasingly competitive market.

Comparison of Different Types of Cam Switches and Their Applications

In the realm of industrial control and electrical distribution, cam switches play a pivotal role in managing the operational efficiency of various manufacturing systems. According to a report by MarketsandMarkets, the global cam switch market is projected to reach USD 2.5 billion by 2025, growing at a CAGR of 6.5% from 2020. This growth is driven by the increasing need for reliable and customizable switch solutions across multiple sectors such as automotive, aerospace, and machinery manufacturing.

Cam switches come in various types, each tailored for specific applications. For instance, rotary cam switches are designed for positions in machinery where a quick change in the operational status is essential. In contrast, modular cam switches offer flexibility, allowing users to configure multiple functions within a compact design. A recent study from Grand View Research highlights that manufacturers are increasingly favoring modular designs due to their adaptability and ease of installation. Moreover, the demand for safety and automation in industrial environments has led to an uptick in the usage of electronic cam switches, which provide enhanced control and monitoring capabilities. With an array of options available, choosing the right cam switch is vital for optimizing performance and ensuring safety in industrial applications.

How Cam Switches Enhance Safety and Efficiency in Industrial Settings

In the fast-paced world of industrial operations, cam switches play a pivotal role in enhancing both safety and efficiency. These switches are designed to provide reliable control over machinery and equipment, allowing operators to manage power distribution effectively. By enabling quick and precise on/off functionality, cam switches minimize the risk of electrical mishaps that could lead to accidents or equipment damage. The intuitive nature of these switches ensures that even operators with minimal training can operate machinery safely, significantly reducing the likelihood of human error.

Moreover, the integration of cam switches into manufacturing processes leads to remarkable improvements in operational efficiency. By streamlining the control of multiple machines from a single point, industries can respond to production demands swiftly, adjusting power as needed without the delays associated with traditional switchgear. This capability not only boosts productivity but also fosters a safer working environment, as the centralized control reduces unnecessary movement around high-risk areas. As businesses strive for greater efficiency and safety in their operations, cam switches emerge as indispensable tools in the modern industrial landscape.

Innovative Trends in Cam Switch Technology for Global Manufacturing

As global manufacturing evolves, the integration of innovative technologies in cam switch design is becoming more critical. The recent shift towards smart manufacturing highlights the significance of interconnected machines that enhance operational efficiency. With new innovations in cam switch technology, manufacturers can optimize processes, reduce energy consumption, and respond rapidly to changing demands. These advancements are not only improving traditional manufacturing practices but are also paving the way for a more agile and responsive supply chain.

Moreover, the ongoing digital transformation, accelerated by the pandemic, has pushed many industries, including manufacturing, to adopt cutting-edge technologies at an unprecedented pace. The rise of automation and smart devices in manufacturing environments means that cam switches must be designed to handle increasingly complex tasks while ensuring reliability and performance. As manufacturers adapt to the 'new normal' anticipated by 2025, those who embrace these innovative trends will likely lead the charge, positioning themselves for greater success in an increasingly technology-driven landscape.